Building a Prefab Container House can be an exciting project. With a budget in mind, it becomes even more essential to plan carefully. These houses offer unique design possibilities and cost savings. However, many underestimate the challenges involved.

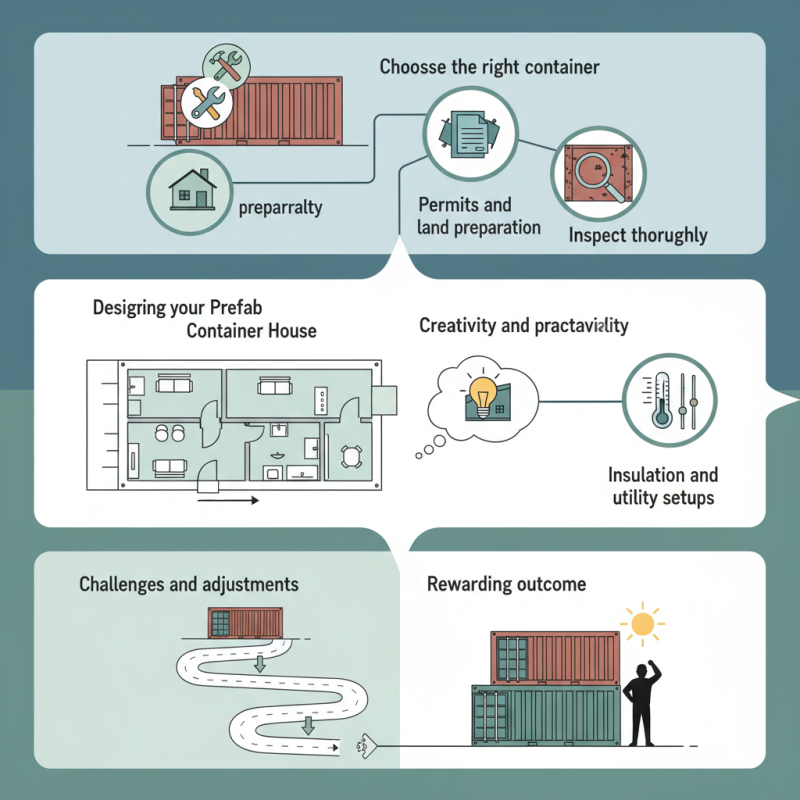

Choosing the right container is crucial. Some containers may have hidden damage or rust. It's important to inspect them thoroughly. Additionally, you need to factor in the costs of permits and land preparation. Overlooking these can quickly lead to budget overruns.

Designing your Prefab Container House requires creativity and practicality. Think about insulation and utility setups. A well-thought-out layout can maximize your space. Yet, achieving your dream home won't be without setbacks. Adjustments will be necessary as new issues arise. Embracing this journey will lead to a rewarding outcome.

Prefab container houses offer an innovative solution for those looking to build on a budget. These structures are made from repurposed shipping containers, providing a durable option for housing. They are often more affordable than traditional homes. However, costs can still escalate if not managed properly. It's vital to plan your budget wisely to avoid unexpected expenses.

One of the key benefits of prefab container houses is their eco-friendliness. They recycle existing materials, reducing waste. These homes can be customized to fit various lifestyles. However, not every design will meet your needs perfectly. Often, one must compromise on space or layout. This might lead to feelings of frustration or regret.

Building with shipping containers also allows for quick assembly. You can set up your home in weeks rather than months. Yet, keep in mind that proper insulation is crucial. Without it, living in a container home can be uncomfortable in extreme weather. Thus, careful consideration of materials and design is necessary to ensure comfort and sustainability.

When considering a prefab container house, choosing the right container size is crucial for your budget. Standard sizes include 20 feet and 40 feet. The 20-foot container is more affordable and easier to transport. However, it may limit your living space. In contrast, the 40-foot container offers more room but comes at a higher cost. Make sure to evaluate your space needs carefully.

Think about the type of container as well. There are standard, high-cube, and refrigerated containers. High-cube containers provide extra vertical space, which can create a more spacious feel. On the other hand, refrigerated containers are pricier and may not be necessary unless you have specific needs. Reflect on how you'll use your space before making a decision. This can save you money in the long run.

Remember to factor in additional costs like insulation and windows. You may find yourself reconsidering your choices as these elements can add up quickly. Budgeting for all components is essential. A smaller, more affordable container might fit your financial plans better but can feel cramped. Balancing your desires with your budget is key to achieving a functional and comfortable living space.

When planning your prefab container house, layout and design are crucial. A well-thought-out layout can maximize both space and comfort. Research shows that nearly 35% of container home builders prioritize open floor plans. This allows for more light and a sense of spaciousness. Consider using movable walls to adapt the space for different needs, creating versatility without extra costs.

Tips: Use online tools for 3D designs. This can help visualize your layout. Think about the placement of windows and doors. Natural light can make a small space feel larger and more inviting.

Budget is always a concern. Unexpected costs often arise in construction. According to the Container Home Society, an efficient design can reduce expenses by about 15%. Keep this in mind. Don’t rush the planning stage. A well-considered design can save money on materials and labor. Choose multifunctional furniture to maximize the use of your space. Reflect on how daily activities will flow through your design.

Building a prefab container house can be a rewarding project. However, having the right tools and materials is essential. Start with standard tools like a drill and saw. A measuring tape is crucial for accurate cuts. Don’t forget safety gear, such as gloves and goggles. They protect you during construction.

Materials are equally important. Shipping containers serve as the main structure. You’ll need insulation for temperature control. It's wise to use plywood for interior walls. Keep in mind that not all containers are in perfect shape. Look for signs of rust or structural issues. If you find damage, you may need extra materials, like patches for repairs.

It’s also helpful to have basic electrical supplies. Wiring and outlets are necessary for modern comforts. Choosing the right paint can improve aesthetics. A good coat can both protect and beautify. Plan your budget, keeping extra expenses in mind. Every project has its surprises. Reflect on what works and what doesn’t.

| Item | Description | Estimated Cost (USD) |

|---|---|---|

| Container | Used shipping container for structure | $1,500 |

| Insulation | Foam or spray insulation | $300 |

| Windows | Standard sized windows | $400 |

| Doors | Steel doors for security | $250 |

| Electrical Wiring | Basic wiring and outlets | $200 |

| Plumbing Supplies | Pipes and fixtures | $500 |

| Roofing | Metal sheets or shingles | $600 |

| Flooring | Plywood or laminate | $350 |

| Tools | Basic construction tools | $250 |

| Total Estimated Cost: | $4,150 | |

Building a prefab container house on a budget is an achievable goal. To save costs, focus on the essential components first. Research shows that reducing square footage can cut expenses by about 15%. Consider a design that maximizes space usage without unnecessary additions. Modular designs can simplify construction and lower overall costs.

Purchasing used shipping containers can lead to significant savings. The average cost for a new container is around $5,000, while used ones can be around $3,000. Inspect your containers carefully. Look for structural integrity and potential modifications needed. It might save you money in the long run.

DIY projects can further reduce expenses. While labor costs can account for up to 40% of total budget, doing it yourself can help. Yet, be cautious about skill level. Ensuring quality in construction is crucial. Sometimes, cutting corners leads to higher repair costs later. Proper planning and budgeting are key to building an efficient prefab container house.