When it comes to ensuring the optimal performance of your geyser, one of the critical components to consider is the Geyser Inlet Valve. This valve plays a vital role in regulating the flow of water into the geyser, ultimately impacting its efficiency and lifespan. Choosing the right Geyser Inlet Valve is essential not only for functionality but also for energy conservation, ensuring that you get the most out of your heating system.

In this guide, we will explore the key factors to consider when selecting a Geyser Inlet Valve, including size, material, and compatibility with your geyser model. Additionally, we will discuss the importance of regular maintenance practices that can prolong the life of your valve and improve overall performance. Whether you are a homeowner looking to enhance your geyser's efficiency or a maintenance professional seeking best practices, understanding the nuances of the Geyser Inlet Valve will empower you to make informed decisions for optimal operation.

The geyser inlet valve plays a pivotal role in home water heating systems. Its primary function is to regulate the flow of cold water into the geyser, ensuring a consistent and effective heating process. By controlling the inlet pressure and flow rate, the valve not only facilitates efficient heating but also helps maintain appropriate water levels within the geyser. This ensures that the system operates smoothly, reducing the risk of overheating and extending the lifespan of the appliance.

Understanding the function of the geyser inlet valve goes beyond its mechanical operation; it encompasses the impact of proper maintenance on overall system performance. A well-maintained valve can significantly enhance energy efficiency, as it ensures optimal water flow and minimizes heat loss. Regular inspections and cleanings are crucial to prevent sediment buildup and potential blockages that could hinder performance. Ultimately, recognizing the valve’s role and committing to its upkeep leads to improved energy consumption and reliability in home hot water systems.

| Dimension | Value | Description |

|---|---|---|

| Valve Type | Ball Valve | Offers reliable performance and good sealing properties. |

| Material | Brass | Durable and corrosion-resistant for long-term use. |

| Size | 1/2 inch | Common size for residential geysers. |

| Pressure Rating | 150 PSI | Suits most standard residential pressure systems. |

| Maintenance Frequency | Every 6 months | Regular checks can prolong valve life and performance. |

| Installation Cost | $50 - $100 | Cost may vary based on labor and region. |

| Lifespan | 10-15 years | Dependent on water quality and maintenance. |

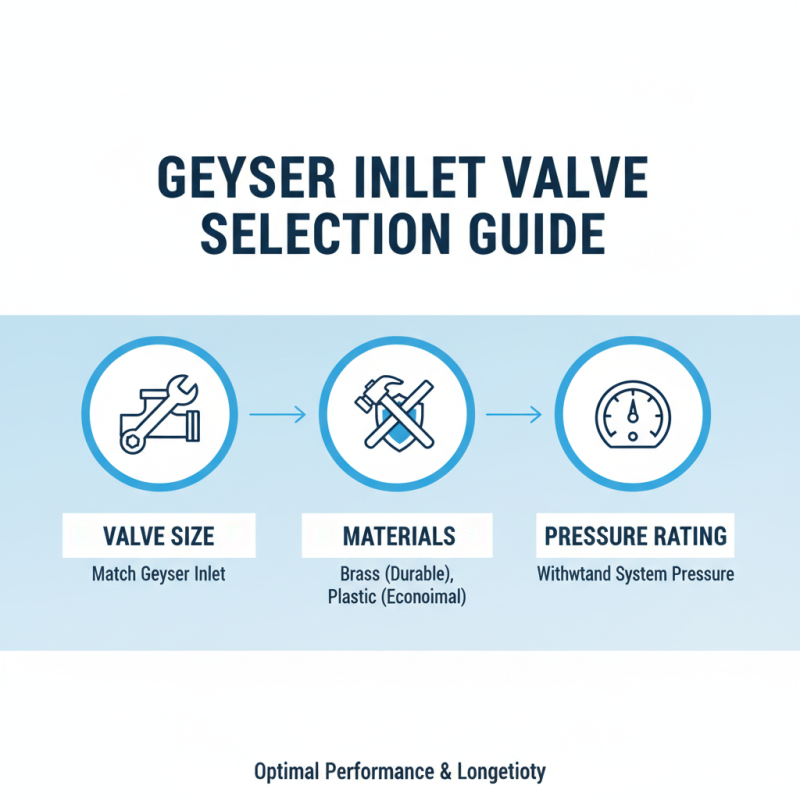

When selecting a geyser inlet valve, several critical factors must be considered to ensure optimal performance and longevity of your geyser. Firstly, the size of the valve is essential; it should match the inlet size of your geyser to prevent leaks and ensure efficient water flow. Additionally, consider materials such as brass or plastic; brass valves tend to offer better durability and resistance to corrosion. The pressure rating of the valve is another key component, as it must withstand the pressure levels in your plumbing system.

Tips: Always check the temperature and pressure specifications of the valve to match your geyser’s requirements. This can significantly enhance its performance and lifespan.

Another important aspect involves the ease of installation and maintenance. Choose valves that come with clear installation instructions and ensure they have accessible fittings for easy servicing. Regular maintenance checks, such as inspecting for leaks or signs of wear, can help avoid sudden failures. It's also beneficial to look for valves with replaceable components, which can save you time and money in the long run.

Tips: Schedule periodic maintenance to catch any potential issues early. Keeping a close eye on the condition of the valve ensures that your geyser operates efficiently, extending its overall lifespan.

Installing a geyser inlet valve is essential for ensuring optimal performance and longevity of your water heating system. Begin by gathering the necessary tools and materials, including a wrench, Teflon tape, and a bucket to catch any drips. Before starting the installation, ensure that the water supply to the geyser is completely shut off. This is crucial to avoid any spills or accidents during the process.

Once everything is in place, remove the existing inlet valve, taking care to drain any residual water from the geyser. Clean the threads on the geyser and the new inlet valve to ensure a secure fit. Wrap Teflon tape around the threads of the inlet valve to create a watertight seal. Carefully screw the new valve into place, ensuring it is tight but not over-tightened, as this could damage the threading. After installing the valve, turn the water supply back on slowly and check for leaks. Make any necessary adjustments to ensure a proper seal.

Finally, it's important to regularly maintain the inlet valve. Periodically inspect the valve for any signs of wear or leaks, and clean it as needed to remove any buildup. Proper maintenance not only extends the life of the inlet valve but also enhances the overall efficiency of your geyser, ensuring you have a reliable source of hot water when you need it.

Routine maintenance of a geyser inlet valve is crucial for ensuring optimal performance and longevity of the water heating system. According to a report by the International Journal of Engineering Research and Technology, approximately 30% of geyser failures can be attributed to neglecting regular maintenance of components like inlet valves. A good maintenance routine should include regular inspections for leaks, corrosion, and wear. Homeowners should check the valve seals at least once every six months to detect any signs of deterioration. Failure to address these minor issues promptly can lead to major leaks or system malfunctions, resulting in costly repairs.

Additionally, flushing the inlet valve periodically is essential for removing mineral buildup that can impede water flow and efficiency. The Water Quality Association suggests that mineral deposits can reduce heating efficiency by up to 15% if not regularly cleared. To maintain optimal performance, it is recommended to flush the valve every 6 to 12 months, depending on water hardness levels in your area. By incorporating these simple yet effective maintenance tips, homeowners can significantly enhance the efficiency and lifespan of their geyser systems, while also optimizing energy consumption and reducing utility costs.

When it comes to maintaining optimal performance in your geyser system, recognizing the signs of wear in the inlet valve is crucial. A study by the International Association of Plumbing and Mechanical Officials (IAPMO) indicates that up to 30% of water heating inefficiencies may stem from faulty inlet valves. Key indicators of wear include leaks, reduced water flow, and unusual noises during operation. If you notice any of these symptoms, it’s essential to assess the condition of your inlet valve promptly.

The lifespan of a geyser inlet valve typically ranges from 5 to 10 years, depending on factors such as water quality, usage frequency, and maintenance practices. A report from the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) emphasizes that many homeowners overlook routine inspections, which can lead to premature failures and costly repairs. Regularly checking for corrosion or mineral buildup can help extend the valve's life. Moreover, replacing a worn or damaged inlet valve not only ensures efficient water heating but also contributes to the overall energy efficiency of the system, potentially lowering utility bills by up to 15%.